Stretch film breaks and tears are common for many businesses.

That means potential wastes that can be detrimental to your bottom line.

The good news—it is preventable.

But to prevent film tears, It is imperative for us to learn all the possible reasons and at which stage stretch film breaks or tears.

When Stretch Film Breaks at the Production of Films

Film breaks at the beginning of the chain happen with a cost to resin converters or stretch film manufacturers.

From production breakdowns to excessive wastes, film breaks and tears are unwanted.

Here are some possible factors.

And how we solve it at Thong Guan to ensure our customers get the best of our films.

Reason #1: Heavy unwind force builds up

The implication of uncontrolled unwind force may cause build-up tension (the stickiness) on the films during the transportation of the rolls of stretch films to customers.

The film’s heavy unwind force (or unwanted tension/stickiness) may cause film breaks during unwinding for packing.

Also, it could cause the containment force applied during wrapping, not optimal, leading to film tears during transportation, which means damaged goods on arrival.

As the consequences are down the line to the end customers, which are costly to brand owners, we must solve this at the production level.

We solve this by controlling the cling level through tension control of the machine during winding of the films into rolls.

In other words, we are reversing the process of force building during transportations.

As such, ensuring good quality films to our customers.

Reason #2: Gels on films produced

From the beginning of the film production, the plastic resins (or pallets) are melted and extruded into films.

Quality control is of utmost importance to Thong Guan from the get-go.

At the start-up, where temperature differences may occur or film size changes during production, unmelted resins may happen.

When the unmelted resins get extruded on the film, gels occur. They can be rather small that sometimes it is not visible to the naked eye.

The consequence is that the gels may cause holes that lead to films snapping during wrapping.

To solve this, there are three possible methods:

1) Segregating the start-up batches or changeover batches

2) Use a better filter to ensure unmelted resins are filtered out

3) Ensure proper schedule of changing the filters

Reason #3: Uneven thickness on films

Film extrusions are complex.

Problems in extrusion may occur from within the die.

Films extruded may be uneven that leads to a whole range of consequences.

As such, consistency is key.

Many manufacturers rely on the operators’ skills to adjust the T-die extruder.

However, potential human error may occur.

With improper adjustment of the T-die, the extrusions of the melted resins may cause variations in the film thickness.

Films with uneven thickness cause films to snap easily during unwinding or wrapping.

At Thong Guan, as we move towards industrial 4.0, we want to automate as many of our processes as possible to ensure no room for human errors.

As such, we use an automatic die controller that auto-calibrates the T-die extrusion to ensure consistency.

Again, we want to ensure the best quality films are shipped to our customers.

Film Tears & Breaks Implications & Preventions

There are many types of breaks—edge breaks, centre breaks, tension breaks, and more.

One can troubleshoot to understand why your film breaks.

However, there’s a saying—prevention is better than cure.

Therefore, you need to get it right from the get-go.

From raw materials pallets to casting, film properties, wrapping machine, loads, packing process, and delivery environment, it matters to ensure you achieve optimum wrapping without film breakage.

As we know from the above, many film breaks and tears could be caused by the quality of the film.

To sum up, common prevention for production cause factors may include

- Using quality resins,

- Stretch films produced with strict quality control,

- Your film extrusion parameter settings,

- Ensure proper machine settings—unwinding speed, optimum tension, unwinding tension, etc.,

- Has quality check & control to ensure consistent film thickness,

- Set up the automated calibration of your extruders, and

- more.

There are many ways to prevent stretch film breaks.

However, businesses must look at the entire operations holistically.

As such, besides buying quality films for your wrapping operations, there are film breaks occurrences during application you need to review to prevent it.

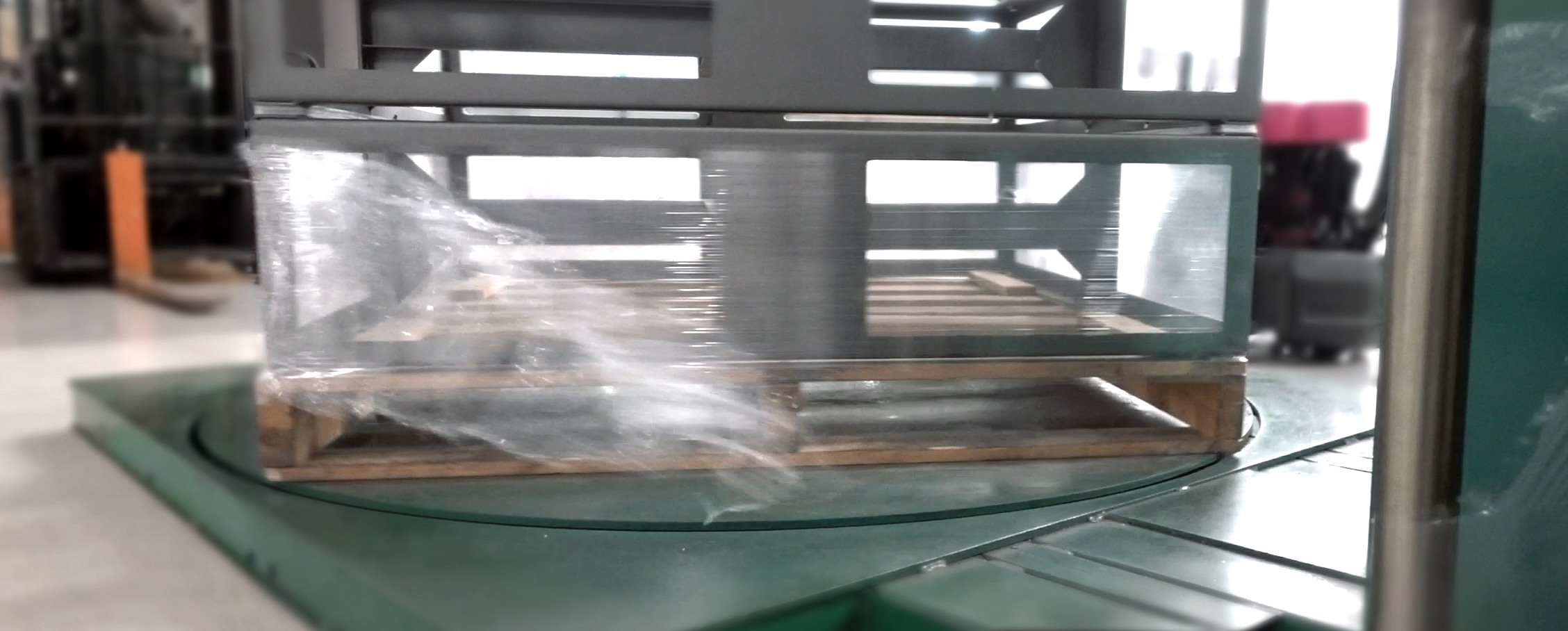

When Stretch Film Breaks During Applications

Reason #4: Inconsistent air supply into the pneumatic panel

When wrapping on automatic wrappers, the entire wrapping applications rely heavily on your machine settings.

One of the settings is the application time that uses a pneumatic system.

A “jerk reaction” may occur during wrapping that leads to tearing the film during wrapping.

The “jerk reaction” of the pneumatic system is caused by the aftereffect of air concussion and non-motion build-up—potentially due to the velocity variance, friction forces, and more on the system.

Simply put, inconsistent air supply into the pneumatic system leads to potential film tears.

This usually is not a problem for thick gauge films.

However, on thin gauge films, the likeliness of snapping is high.

Reason #5: Overstretching the limits, breaking the thresholds

Every stretch film comes with a set of properties and thresholds.

Overstretching your films will definitely lead to a high risk of film snapping during wrapping, if not film breaks during in-transit.

Using wrong films for wrapping applications is also common.

As much as we know the importance of packing your goods securely, this industry lacks visibility and traceability.

So, brand owners are left wondering.

- What properties do your films carry?

- How do you know the limit thresholds of your films?

- What is the optimum stretch of your film?

- What are the optimum resolutions per pallet?

- What films to use for different types of loads?

- How do I increase repeatability for optimum wrapping consistency?

Well, Thong Guan, in partnership with Newton Research Centre, may have the answers.

Stay tuned for our upcoming announcement.

For more info or inquiries, please contact info@thongguan.com.