Defining the differences between PCR & PIR is critical to the entire plastic recycling operation.

Plastic packaging manufacturers or converters are increasingly pressured to incorporate recycled plastics in their products today.

Take the recent PPT announcement by the UK Government.

While on the other side of the globe, the McGowan Government announced their fast-tracked Western Australia’s Plan for Plastics on 13 June 2021.

Sustainability is becoming inherently critical for businesses. Not just for branding but also business continuity and profitability.

However, customers like brand owners and packagers are still very concerned with costing and profits in this competitive market.

That is fair. Business is business.

Some of the concerns revolve around.

How does the presence of recycled materials affect the mechanical properties of plastic packaging?

Can recycled plastics perform as well as virgin plastics packaging?

Can recycled plastic packaging achieve the same quality functions as plastics made from virgin resins?

Will using recycled materials packaging keep my cost low?

How do manufacturers achieve our film requirements?

These concerns are real.

Thong Guan would like to address some of these through our latest article series—#RecycledPlasticSeries.

In the first article of the series, we want to address the nitty-gritty of introductions.

Plastic, a valuable material

Plastic is a commodity today.

Imagine packaging your products with other materials besides plastics.

They were invented in 1907 for a reason—or many reasons that grew over the years.

Here are some of the critical advantages of plastics over other alternatives we’ve shared during our #LiveGreen Launch.

Despite its superiority over other alternatives, plastic remains a controversial material to date.

One of the primary reasons is ocean contamination and Earth pollution.

As such, we cannot stress enough—plastic is not the problem!

Poor plastic waste management is the problem!

And efficient waste management of plastic cannot be done by a single stakeholder.

Therefore, Thong Guan relentlessly finds ways to incorporate sustainability from the company culture perspective and business ecosystems—processes, policies, communities, products, innovations, and more.

What is virgin, bio-based, PIR and PCR plastic resins?

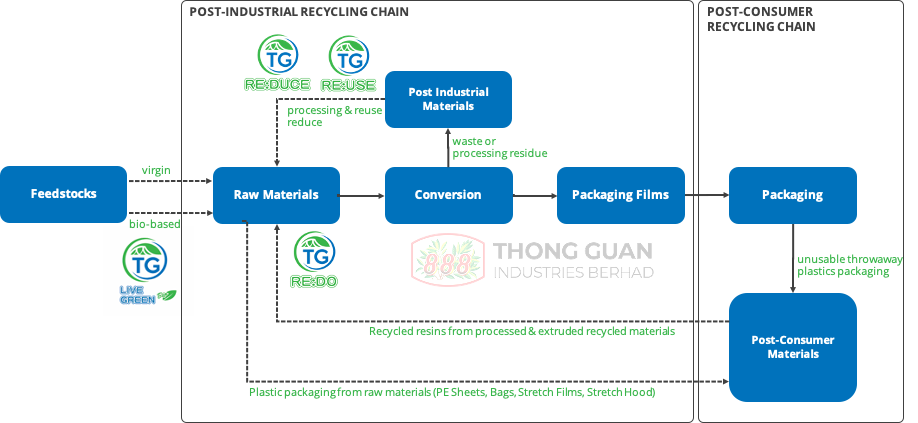

To manage our plastic wastes efficiently, we first need to understand the differences between PCR & PIR. With comparisons to virgin resins and recycled resins in the industry.

We can loosely interpret them as

- Virgin Plastic Resins are from petrochemical feedstock. For instance, natural gas or crude oil that has never been used or processed before.

Bio-based Plastic Resins are made from green or renewable feedstocks, e.g. crops, woodchips, and more.

Thong Guan is proud to say we use green bio-based resins. They are made from the waste of the paper industry—hence, closing the loop, in a way. If you’re interested in our bio-based range products, check out our Nano Series and inquire about getting them bio-based.

We have also been producing garbage bags made out of sugarcane-based resins.

- Post-Industrial Recycled (PIR) Plastic Resins are made from plastic wastes generated during the manufacturing process and never left the production.

In ISCC Plus (link to ISCC website) terminology,

“Post-industrial material [waste or processing residues] covers e.g. material derived from waste streams during the system user’s manufacturing processes. Material that is reused in the same production process and/or can be assigned to the categories of rework, regrind or scrap generated cannot be claimed as circular.”

- Post-Consumer Recycled (PCR) Plastic Resins are made from wastes that consumers throw out when no longer usable for their intended purpose.

In Thong Guan, we collect and process post-consumer wastes from our raw ingredients packaging and suppliers.

Then we turn them into recycled resins for our plastic bags.

In ISCC terminology,

“Post-consumer material is defined as material generated by households or by commercial, industrial, and institutional facilities in their role as end-users of the product which can no longer be used for its intended purpose. This includes returns of material from the distribution chain.”

Here’s a simple diagram to illustrate the flow of various materials in the production and distribution chain. This shows the significant differences between PCR & PIR based on their value and environmental impact on the chain.

Differences Between PCR & PIR and the Types of Resins in a Nutshell

The waste or processing residues generated in-house from the waste stream of manufacturing processes is known as post-industrial.

They are reused in the same production process and can be assigned to rework, regrind or scrap generated. These materials cannot be claimed as circular.

Bottomline

Knowing the differences between PCR & PIR is critical.

It helps us to ensure our policy and practices are in place accordingly.

This way, we meet not just our own standards but also global and governmental legislation.

At Thong Guan, we ensure PIR practices to reduce our in-house waste as part of our sustainability culture.

On the other hand, for post-consumer materials, the keyword here is “no longer usable for its intended purpose”.

This includes

- returning materials from the distribution chain,

- plastic packaging materials that come with our production raw materials.

PCR is one of our #LiveGreen goals for its most ideal and practical approach towards sustainability.

As we have embarked the same with our blown film, Thong Guan is working relentlessly to incorporate PCR into our stretch films while meeting our customers’ film requirements.

This article is part of our #RecycledPlasticsSeries. You may access all the articles under this series by searching for #RecycledPlasticsSeries.