Starting Out

The year was 1942. From the nook of a provincial town in Kedah, the journey of an unassuming pursuit began.

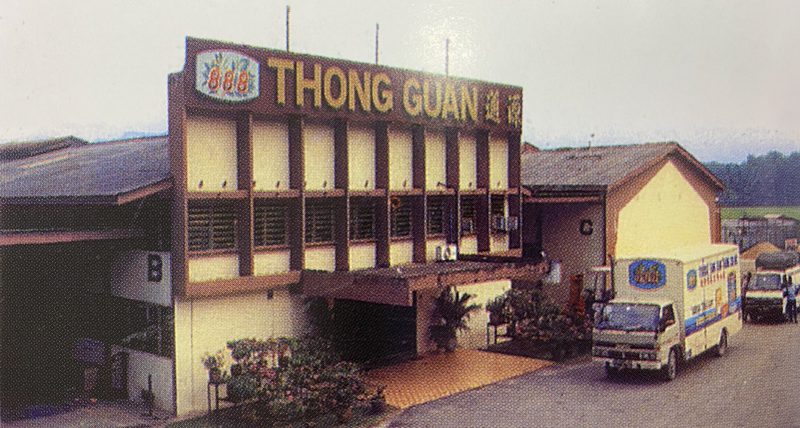

Mr. Ang Thong Guan, an ambitious, dedicated young man, started selling tea in his beat-up bicycle in a small town called Sungai Lalang.

Upon seeing his business grow, he bought the company’s first Chevrolet van.

In 1945, his sons Dato’ Ang Toon Cheng and Dato’ Ang Toon Piah joined him in this little family business.

Together, they expanded the tea business to the Northern Region of Peninsular, Malaysia.

Within three years, the company gradually grew and developed a marketing network with a fleet of vans that distribute beverages and consumer products to grocery and coffee shops, food outlets and general traders.

Diversifications

By the 60s, the company diversified their offerings by entering the plastic industry.

It was the start of a journey towards becoming one of the largest plastic packaging manufacturers in Malaysia and the fastest growing companies in Asia Pacific.

The company ventured into the manufacturing of plastic products like raffia strings and drinking straws, and later expanded the product range to include plastic ropes, plastic bags and sheets, paper serviettes and cologne paper towels.

Making A Difference With Strategy

Since the fledgeling enterprise of plastic packaging, Thong Guan started TG Flexible, a flexible packaging division in 1972.

From then onwards, TG Flexible ventured into making all types of flexible plastic packaging and services for both industrial and consumer use.

In 1997, Dato’ Ang Poon Chuan was elected as the Managing Director of Thong Guan Industries.

Under his helm, the company ventured into stretch film production for industrial pallet packaging and unitization.

TG Stretch was a strategic move as more multinational corporations were established in Sungai Petani, Kedah after 1997.

Thong Guan played a pivotal role during the industrialisation of Malaysia.

As the years when by, the business grew tremendously well. It was also in the same year that the company got listed on the Kuala Lumpur Stock Exchange (KLSE).

In 2010, we merged the manufacturing plants of both TG Flexible and TG Stretch for more sustainable production and management where administrative costs and production waste were greatly reduced.

The team has, over the years, worked relentlessly towards bringing quality plastic produce and value-added services to our customers.

We also continuously employ industrial best practices and strict quality control processes. To date, the company has been awarded various certifications like ISO 9001, ISO 14001 & ISO 45001 and many others.

Innovative Solutions: The Convergence Of Experience, Knowledge & Innovations

In 2016, the team decided to further develop their acquired expertise and knowledge in the stretch film industry to help their customers.

Hence, a research centre equipped with state-of-the-art equipment for simulated testing was established.

The research and development centre focuses on providing simulated testing, consultation, and services in cost-effective pallet packaging and unitization.

Through the analysis, the centre also designs and develops the best packaging solution for your products from primary to tertiary packaging.

Thong Guan will progressively and steadily work towards building an enduring business through strong partnerships and innovation.

CONTACT US TODAY

Milestone

1942

1960s

1970s

1980s

Expanded trading and manufacturing operations to Kota Kinabalu, Sabah with the opening of the market in East Malaysia.

1993

1995

1997

2000

2002

2003

2005

2006

2007

2009

2010

2011

2014

2015

2016

Commissioned 5-layers blown film line to produce film for automatic packaging machine, lamination film, and stretch hood.

Commissioned the first continuous noodle-making line in new factory in Sungai Petani.

2017

Set up representation office in Europe to expand the European market share.

2018

2019